Plastic Injection Molding Services

What is Plastic Injection Molding?

- Our plastic injection molding services are designed to deliver precise, durable plastic components for industrial, commercial, and consumer applications. The process involves injecting molten plastic resin into a custom steel mold, allowing complex shapes to be produced with high accuracy and consistency.

- With advanced molding equipment and in-house mold machining capability, we ensure every project is optimized for quality, efficiency, and repeatability. Our goal is to provide manufacturers in Jordan, UAE, KSA, and the United States with reliable, cost-effective molded solutions that meet international standards.

Why Choose JO MFG’s CNC Milling Services

- At JO Manufacturing, we provide precision CNC milling services in the Middle East. Our Multi-axis machining centers deliver exceptional accuracy, surface finish, and consistency across every production run.

- Businesses choose us for our reliable turnaround, consistent quality, and strong communication, ensuring every project moves smoothly from concept to completion.

Benefits of Our Plastic Injection Molding Services

High Repeatability, Once a mold is established, parts can be produced consistently and accurately in large quantities.

Precision and Stability, Controlled injection parameters ensure reliable dimensional accuracy and surface finish.

Material Versatility, Supports a wide range of thermoplastics to suit structural, functional, or aesthetic requirements.

Efficient for Scaled Production, Best suited for medium to high production volumes where uniform quality and efficiency matter most.

In-House Mold Machining Capability, Enables close control over mold quality and quicker adjustments during development.

Run Existing Molds, If you already have a mold, we can operate it to produce parts efficiently without needing to create a new tool

Ready to bring precision to your next project?

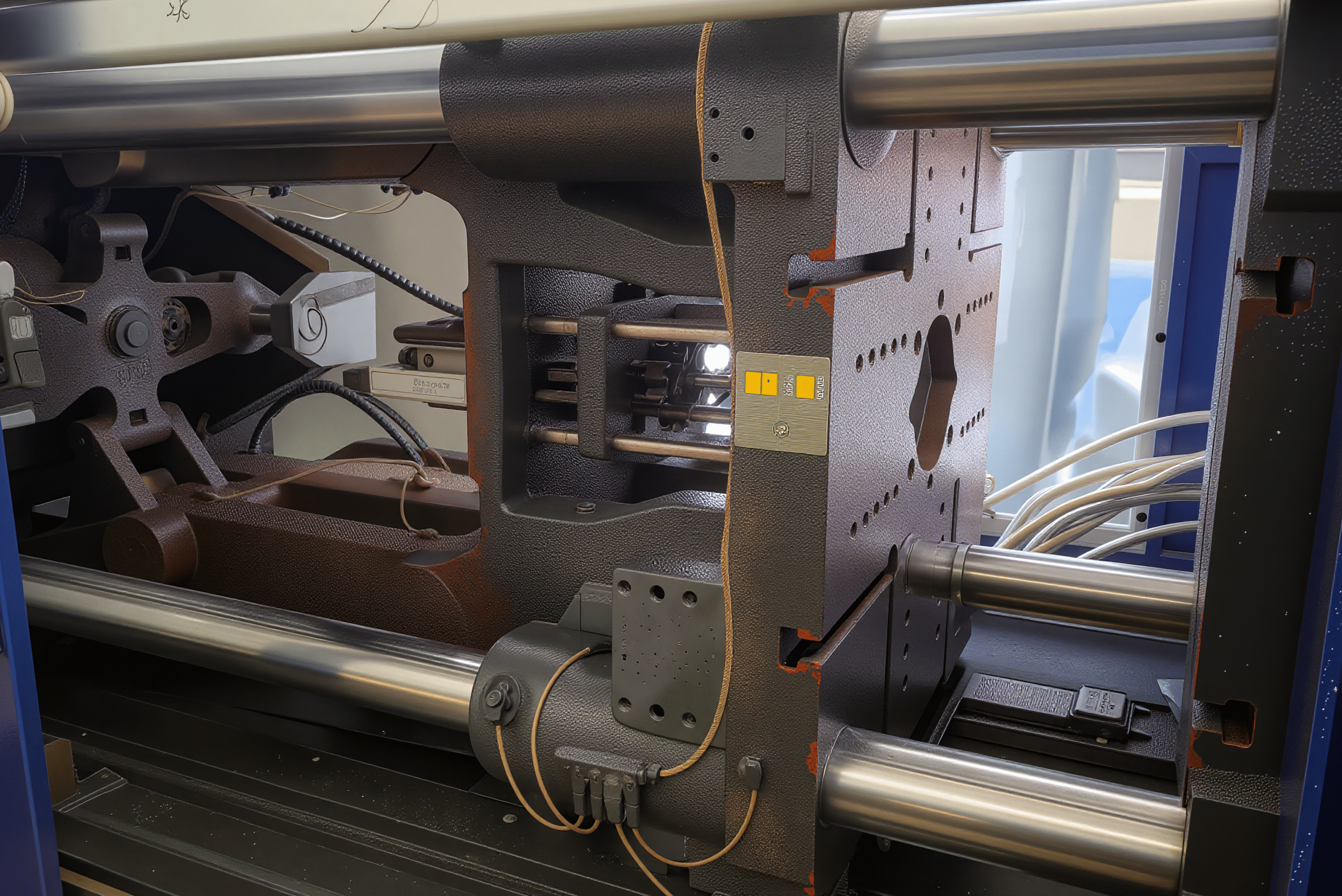

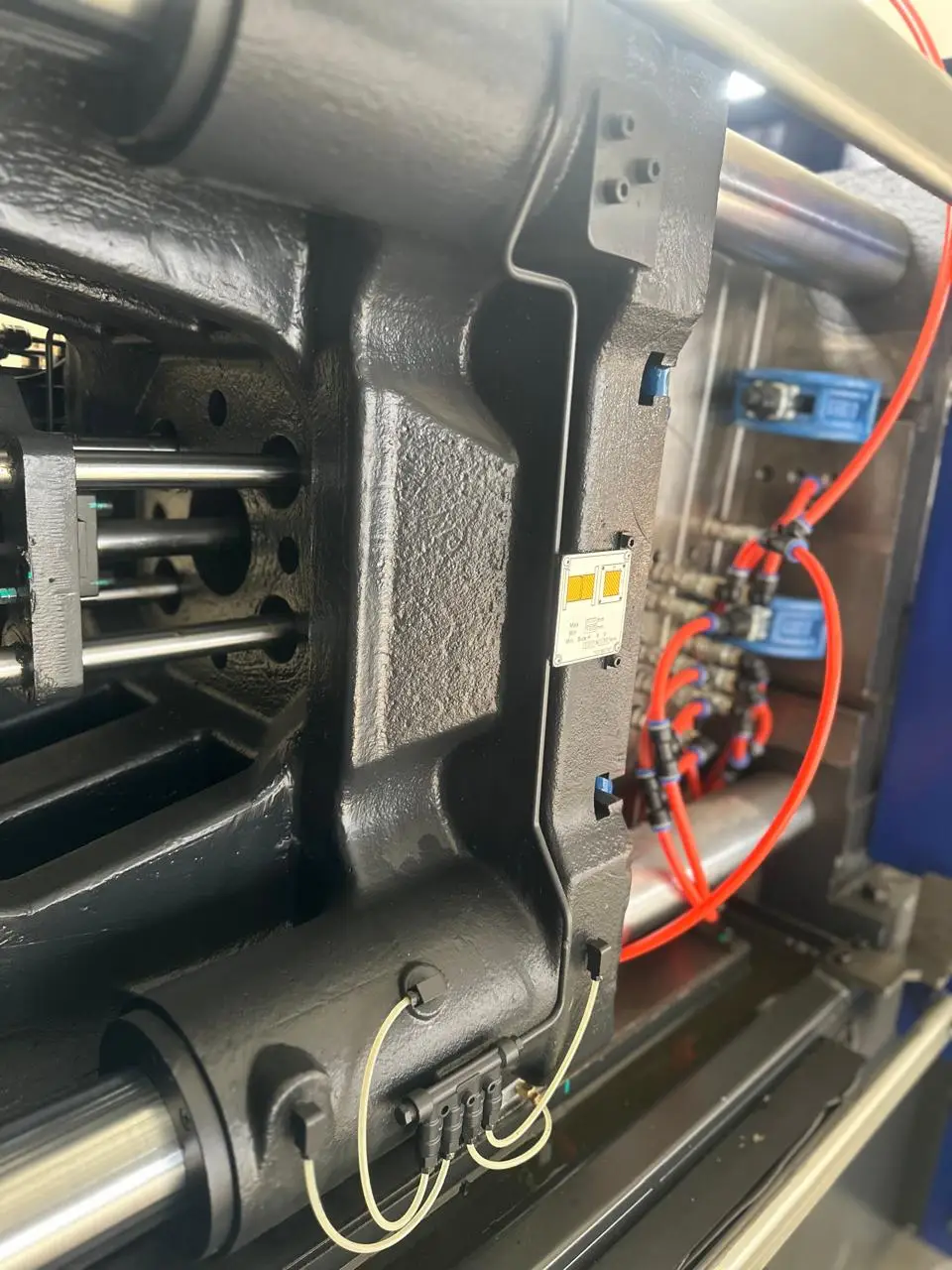

Max Dimensions for Haitian MA1600/570

- Machine Size: 570 (distance between tie bars is 570 x 570 mm)

- Theoretical Shot Size: 319 cm^3

Plastic Injection Molding FAQ

Plastic injection molding is a process where molten plastic resin is injected into a mold to produce precise, repeatable parts with complex shapes and consistent quality.

We work with a wide range of thermoplastics, selected based on strength, durability, and surface finish requirements.

Standard production typically takes 2–4 weeks, while mold development will take 10-12 weeks.

Yes. Expedited production may be possible depending on machine capacity and mold availability.

Yes. If you already have a mold, we can operate it to produce parts efficiently without creating a new tool.

Features such as threads, inserts, ribs, bosses, snap-fits, and undercuts can be incorporated depending on mold design.

For cross checking part tolerances we will need a PDF or DXF file detailing are part features.