CNC Lathe Turning & Milling Services

What is CNC Lathe Turning & Milling?

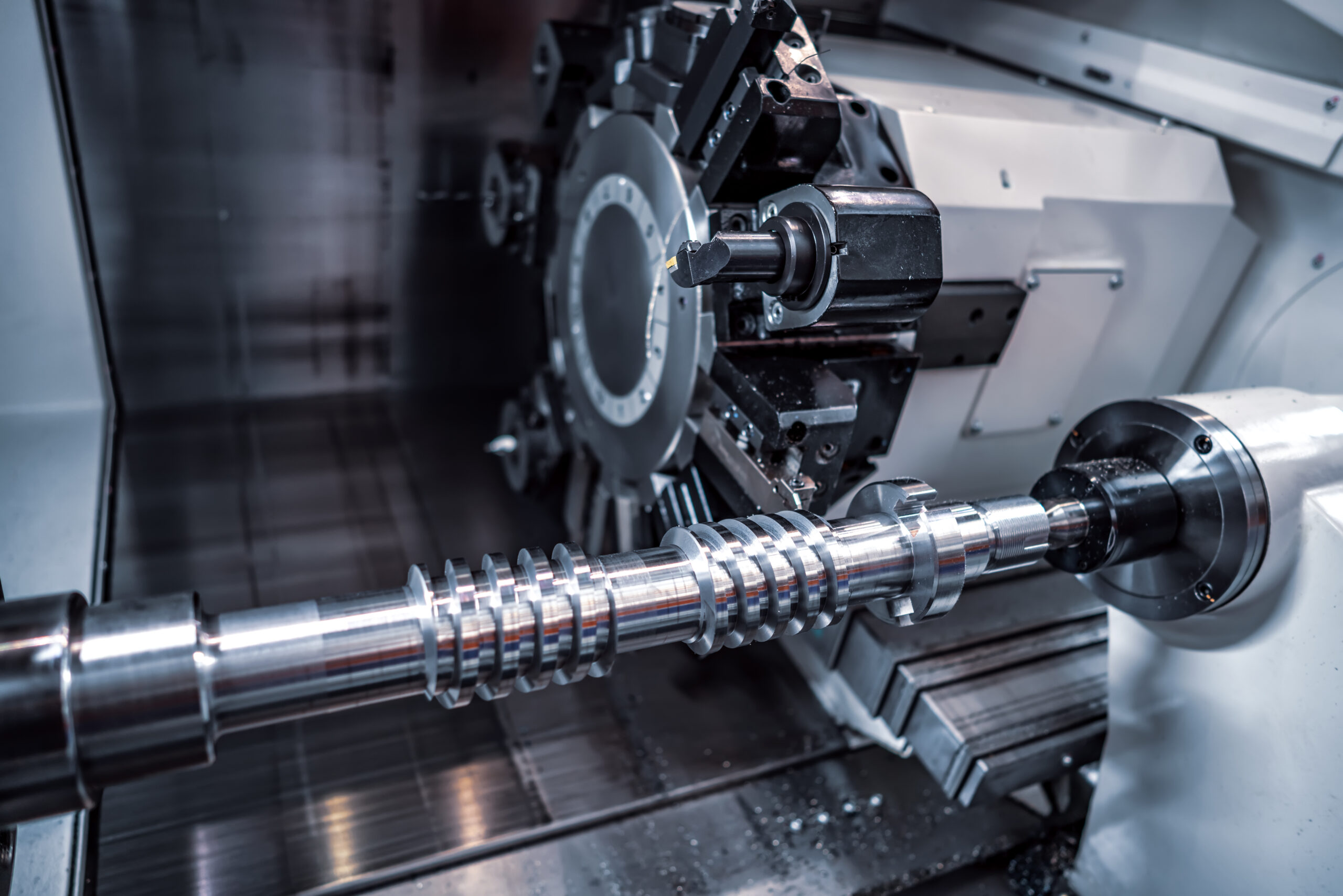

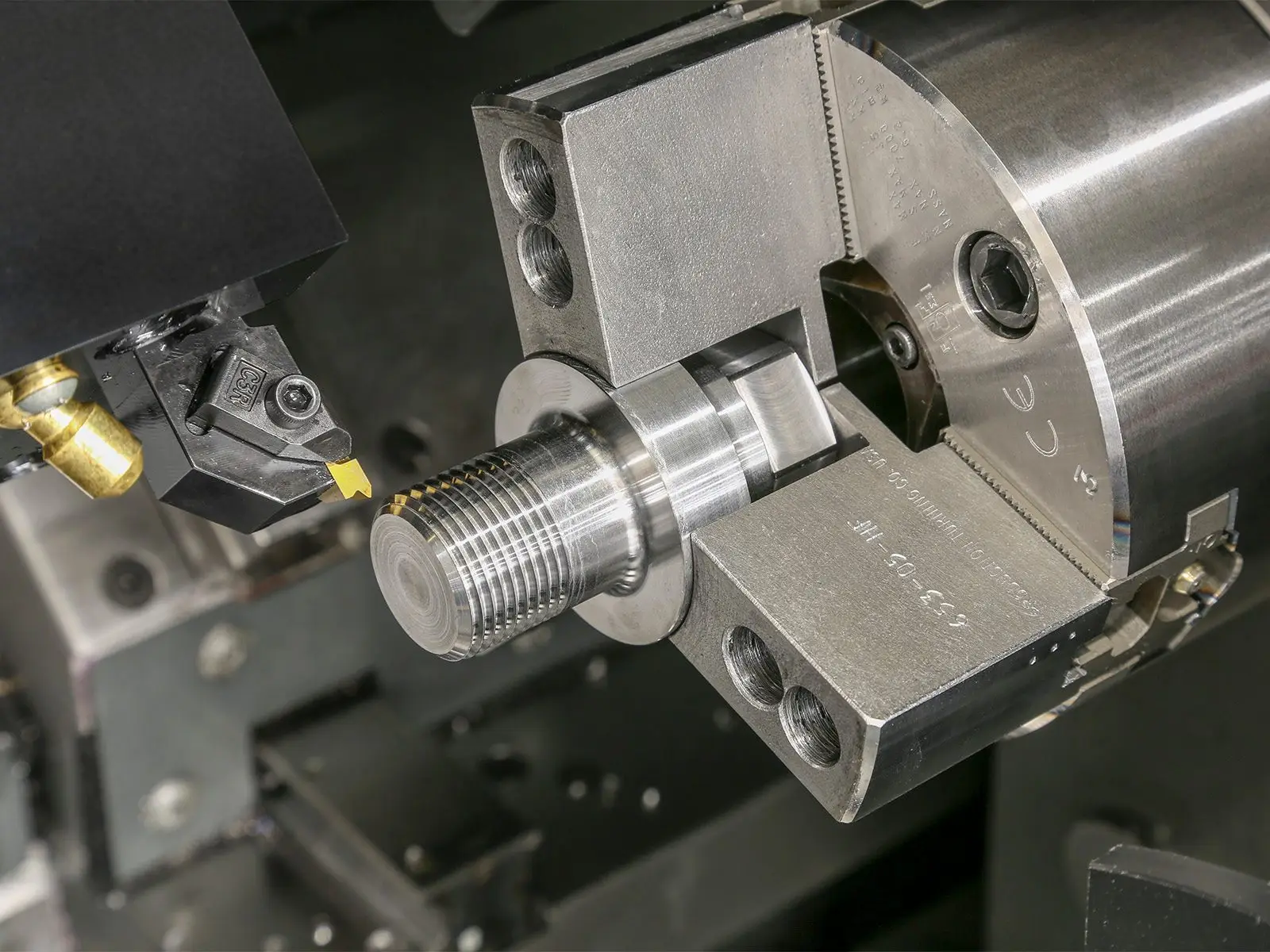

- Our CNC lathe turning and milling services provide precise, efficient machining for round metal components in carbon steel, stainless steel, and aluminum. Using modern turning centers with live tooling, we can perform both turning and milling operations in a single setup, reducing lead times and ensuring exceptional accuracy.

- This integrated process allows us to produce complex geometries, threaded features, and multi-faced parts with tight tolerances and clean finishes, all while maintaining consistent quality across production batches. Trusted by industrial clients in Jordan, the GCC, and the United States, we deliver precision metal parts that meet international standards for performance and reliability.

Why Choose JO MFG’s CNC Milling Services

- At JO Manufacturing, we provide precision CNC milling services in the Middle East. Our Multi-axis machining centers deliver exceptional accuracy, surface finish, and consistency across every production run.

- Businesses choose us for our reliable turnaround, consistent quality, and strong communication, ensuring every project moves smoothly from concept to completion.

Benefits of Our CNC Lathe Turning and Milling Services

One-Setup Efficiency, Combined turning and milling operations reduce errors, and lead time.

High Dimensional Accuracy, Maintain tight tolerances for critical diameters, threads, and mating surfaces.

Versatile Machining Capability, Ideal for shafts, bushings, couplings, and complex multi-feature components.

Smooth Surface Finishes, Optimized cutting parameters for clean, consistent results on every part.

Consistent Quality and Repeatability, Rigid process control ensures every batch meets exact specifications.

Trusted by Global Partners, Reliable service and export-ready quality for clients across the Middle East and the United States.

Ready to bring precision to your next project?

Tolerances and Max Dimensions

Max turning diameter Ø298 mm, max turning length 572 mm

Lathe Turning & Milling FAQ

CNC lathe turning is a process where the workpiece rotates while a cutting tool shapes it. Our lathes with live tooling can also perform milling operations in the same setup, reducing handling and improving precision.

We specialize in carbon steel, stainless steel, and aluminum, and can also handle brass and copper upon request.

This process is ideal for shafts, bushings, couplings, threaded components, and complex parts that require both turning and milling in one setup.

We maintain tight tolerances, ensuring precise diameters, threads, and milled features that meet engineering and assembly requirements.

Yes. We can coordinate anodizing, powder coating, or galvanizing through trusted finishing partners for complete, ready-to-use components.

Yes. We accept 2D drawings (DXF , PDF) and 3D CAD files (STEP, STL, F3D).